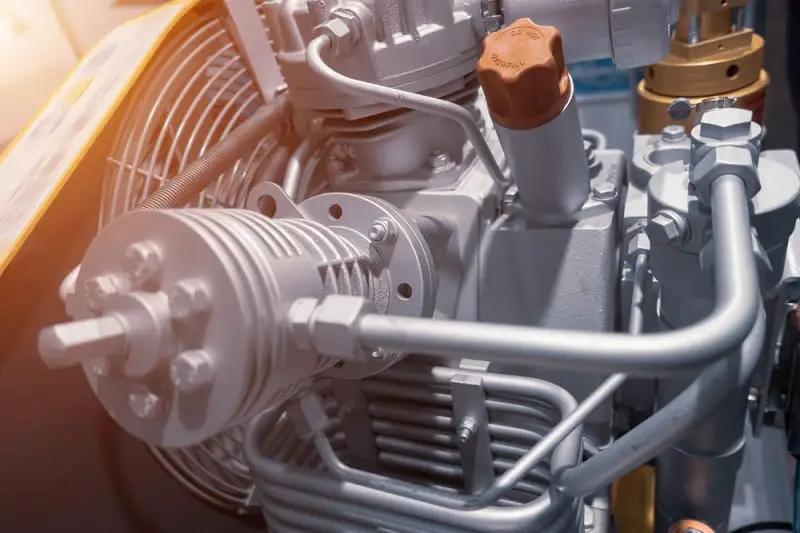

Air Compressor Intake Valve Problem

The intake valve of an air compressor is the most essential part of an air compressor, many compressors have more than one intake valve. They are used on rotatory screw compressors, reciprocating piston compressors, and scroll compressors.

The function of an air compressor intake valve is to let the air freely flow from one side to another, blocking the airflow from the opposite side. The intake valve of an air compressor is designed to control the excess of the flow of air from the system.

If the air compressor is running but failed to perform or building the required pressure the problem might be with the intake valves. These valves control the airflow let it blows from one side to another.

The problem arises when you notice that the air compressor is continuously running and there is not enough pressure building. Why does this happen? Because the pressure in the tank is not reaching the pressure switch to reduce the pressure level. Depending on your air compressor the air intake valves may vary, the small DIY air compressor has two valve plates that is placed between a pair of gaskets. The low-pressure valve helps to control the air intake into the cylinder, entering from intake filter, while a high-pressure HP valve helps the air to head downwards the tank.

Air compressors run but fail to produce the required air pressure you want due to these two reasons:

Damaged Pump

If your air compressor’s motor is perfectly working and there seems no visible fault with its operation but it is not producing enough air pressure. Your air compressor probably has a damaged air intake pump. This problem can occur when the heat inside effects the metal of these valves.

Damaged Gasket

If the air compressor is only generating a little amount of air pressure such as the air is flowing from one to another side without sufficient pressure, the issue might be in between the two gaskets i.e. the low pressure and high-pressure plates of the compressor.

If you notice any of these things happening try solving the problem immediately instead of delaying it. This would pressure inside the air compressor and would do further damage. Fortunately, the pumps and the gasket can be easily replaced.

Having an air compressor and regularly using it means one of many issues arises every now and then. Hence, it is important to perform maintenance regularly. Air compressors help in performing all kinds of professional as well as personal level work. From performing hardcore industrial work to repairing automotive parts or filling air insides the tire, the air compressors provide the optimum level of energy to let you perform these tasks proficiently.