Troubleshooting an Air Compressor That Won’t Fill the Tank

Have you noticed your air compressor struggling to fill the tank up completely? Does it seem to stop at a low PSI no matter how long it’s been pumping air? This annoying problem can come out of nowhere and it can be hard to pin down the exact cause. Luckily there are a few things you can check that will help you determine why your air compressor won’t fill the tank all the way.

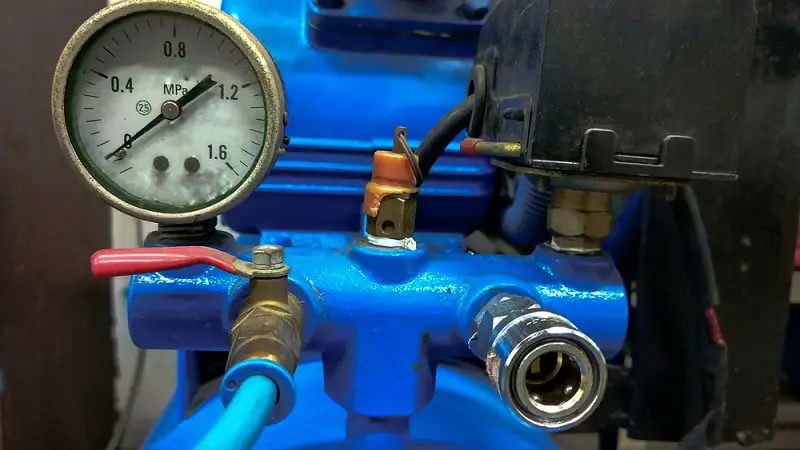

Check the Intake and the Pressure Valves

The intake valve is the mechanism on a reciprocating air compressor that allows air into the chamber when the piston is pulling downward.

If the intake valve is failing, air would be blowing out from the intake port. To check for this, you’ll want to remove the intake filter to get a better chance of feeling the airflow. Then start the compressor, carefully feeling around for any air coming from the intake port.

If there is air that feels like it’s coming from the port, then it is the intake valve that is causing the lack of pressure and will need to be replaced.

The pressure valve works as the opposite of the intake valve. That is, it’s designed to only allow airflow to escape once the chamber is at a specific pressure. To check, first, make sure your air compressor is off and that the tank is drained. Remove the line that goes from the piston head to the tank.

Then turn on the compressor and see if you can completely block the air from coming out of the pressure port. If you can stop the air, it’s a good chance that your pressure valve has gone bad and needs replacing

Checking the pressure valve this way is not a guarantee that there isn’t something else wrong. It’s always a good idea to eliminate the possibility of the other faults in your compressor.

Replace the Gasket

The gasket ensures an airtight chamber so if your gasket is cracked or broken air can easily move around the chamber, preventing your compressor from filling your tank completely.

Even if you open the pump and get a good look at the gasket, it could look completely normal but still falter when under high pressure. The few dollars it will costs to replace would be worth the peace of mind that the gasket isn’t the culprit of your low-pressure issue.

Inspect the Piston Seal

The piston seals are another vital part required to operate perfectly in order to maintain an airtight chamber. If you’re going to open the pump when you’re replacing the gasket, it would be a good idea to also check the seals on the piston for any damage.

If the seals are broken then air could be escaping, or oil could be getting into the air chamber. Either way, they would need to be replaced along with the gasket.

If you don’t see any damage on the seals, then you can leave them as they are. Make sure they’re properly lubricated before putting the pump back together.

Examine the Tank Check Valve

The tank check valve is connecting the tank to the line coming from the pressure port and is designed to only allow air to enter the tank. If this part was malfunctioning, then air could be prevented from entering the tank properly or it could be letting air escape when the pump is off.

If that is the case then a new check valve is needed in order for your air compressor to fully pressurize the tank again.

Related Video: