How an Air Compressor Regulator and Switch Work

As you may well know, there are several key components to a fully-operating air compressor system. Two of those key components that are often misunderstood are the air compressor regulator and the air compressor switch. To help you learn more about the “anatomy” of your system, let’s take a look at how each of these two key components works. Having a firm understanding of how your air compressor works will allow you to better care for and operate your machine with little to no issues.

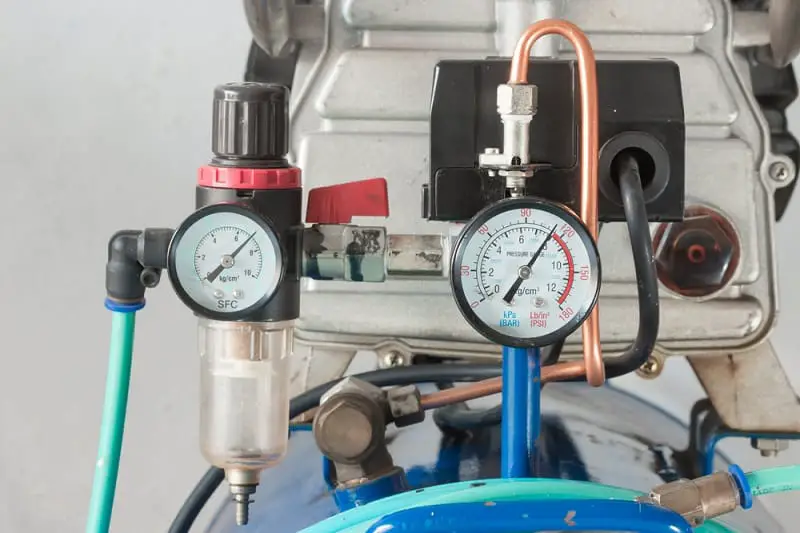

How an Air Compressor Regulator Works

Essentially, the air compressor regulator is responsible for controlling the pressure that flows through your air compressor. If you want to reduce the air pressure on the outlet, you would control the amount of pressure via the air compressor regulator. Furthermore, regulators serve as a pressure stabilizer that provides the correct amount of pressure output, regardless of how high the pressure input may be.

The regulator is controlled manually via what is called a set screw. The regulator controls the amount of air pressure that is allowed to build up in the compressor tank by utilizing springs that connect to the shafts of the set screw. When you turn the set screw, the springs are compressed and pushed down via the regulator, causing the valve to stay open. On the contrary, when the pressure of the springs is released, the valve closes.

When an air compressor is turned on, the air begins to accumulate in the tank, which increases the amount of pressure built up. To ensure that the right amount of pressure is provided for the use of various tools (such as tire pressure machines and drills), the air regulator controls and regulates the amount of pressure provided. This ensures that your tools and air compressor system are not damaged due to extreme pressure buildup.

How an Air Compressor Switch Works

As with the air compressor regulator, the compressor switch is a vital component in the healthy operation of your air compressor. The compressor switch is a mechanical component of the compressor that completes the system’s power circuit and turns power to the motor on and off. These switches included a pressure relief valve which is responsible for relieving line pressure, resulting in an easier start of the motor.

The air compressor switch works much like your everyday light switch. When the switch lever is moved to the ‘auto’ selection, the electrical contacts inside the switch connect, thus completing the circuit and allowing the motor to turn on. With an air compressor, however, the switch also triggers the air compressor to begin pressurizing. Once the specific amount of pressure is reached in the tank, a mechanism inside the switch forces the electrical contacts apart, which breaks the power circuit and stops the motor from operating. This safety mechanism ensures that dangerous amounts of pressure do not build up in the tank. As the pressure begins to flow out of the tank due to operation, the switch system recognizes this and reconnects the circuit, triggering the motor to start up and increase pressure to the originally specific amount.

Related Videos: