Air Compressor Pump & Air Compressor Dryer

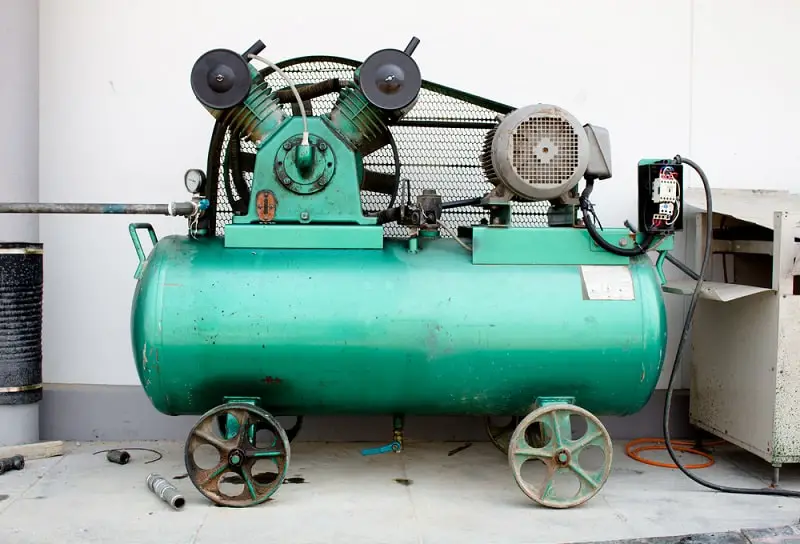

Air Compressor Pump

An air compressor is a mechanical device that reduces the volume of gas and increases its pressure. The compressed gas is then used as a potential source of energy. From our nail guns, drills, and refrigerators, to gas stations and car services shops, we come across air compressors quite often.

Every Air Compressor has these components:

| Component | Purpose |

|---|---|

| Drive | Energy source |

| Pump | Compresses gas |

| Storage Tank | Stores compressed gas |

| Drain Valve | Gets moisture out |

Inside the storage tank, the gas is kept at very high pressure as compared to the pressure in the room. Therefore, as soon as the regulator opens, the gas rushes out. This high-pressure gas is then used as a power source for operating tools or devices.

The drive provides gas or electrical energy to start the compressor. The pump then uses this energy to compress the gas and store it in the storage tank. The compressor has only one valve and doesn’t allow the gas to exert pressure on the pump.

The compressed gas also contains water molecules that are trapped in the tank with the gas. These water molecules condense inside the tank. To get them out, each tank has a drain valve. The drain valve gets the moisture out, maintains gas pressure and prevents corrosion inside the tank.

To regulate the flow of air, there is a pressure switch. A pressure switch in simple words is your ON/OFF button that lets you operate the air compressor. In addition to that, there is a pressure gauge in the air tank. The purpose of the gauge is to measure and monitor the air pressure inside the air tank.

Uses:

The air compressor pump is the most cost-effective and efficient way to save energy. It is used to power tools on construction sites, at gas stations and industrial sites. It is also used in garages, workshops, and service stations. On a domestic level, it is used in everyday tools like spray paint, nail gun, drills, and wrenches.

Air Compressor Dryer

Like an air compressor pump, any equipment that uses compressed air can have moisture build-up inside it. To remove the moisture from compressed air, a device is used that is called an Air Compressor Dryer.

When air is being compressed, its temperature rises. As it cools down, the water molecules trapped inside it starts turning to liquid and can cause corrosion in pipes and tanks. An air compressor dryer removes the excess liquid and moisture, to maximize performance and prevent corrosion.

There are two main types of air compressor dryer based on the drying agent used:

- Refrigerated drying units:

- Desiccant drying units:

Refrigerated Drying Unit

This is the most popularly used air compressor dryer and is used to drain moisture from industrial equipment and pipes. As the name suggests, it uses a cooling method to get the excess liquid and moisture out. There are two further types:

| Cycling | Non-cycling |

|---|---|

| This dryer unit uses two cycles. The first cycle cooled down the air to 35F, and removes moisture. The next cycle reheats the air while keeping dew point in control. | This dryer uses a refrigerant that continually circulates in the equipment removing moisture efficiently. It uses a valve to control the refrigerant. |

| Advantages: Conserves energy. Cost-effective Efficient | Advantages: Conserves energy. Cost-effective Efficient Advantages: Perpetual Performance Maintains dew point Cost-effective |

| Disadvantages: Non-consistent dew point Heating needs more cost | Disadvantages: Non-consistent dew point Heating needs more cost Disadvantages: Energy conservation could use improvement |

A desiccant drying unit uses a desiccant agent to remove moisture by a process called Adsorption.

Desiccant Drying Unit

Depending on its type and functionality, a desiccant drying unit may or may not use heat while removing moisture.

The compressed air enters a valve that contains drying agents like silica gel or activated alumina. The molecules of moisture attach to the drying agents through the process of adsorption.

| Advantages | Disadvantages |

|---|---|

| Consistent dew points Suitable for hazardous equipment | Expensive set-up cost Requires maintain ace |

We hope this information will help you understand the working mechanism of an air compressor pump and air compressor dryer.

Related Video: