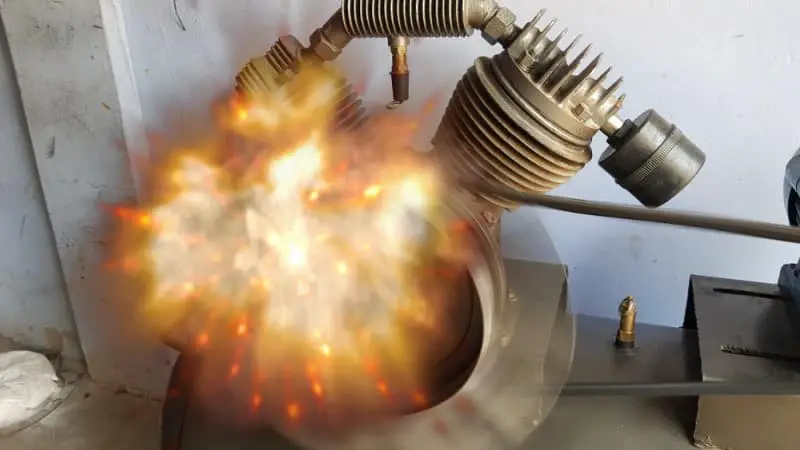

Can an Air Compressor Explode and Blow Up?

There have been various occasions where a tank of a compressor holding air explodes. One of the main causes that result in the explosion of an air tank is the corrosion of the tank from when water condensates. Manufacturing flaws can also be one of the other causes. Fundamentally, these types of accidents are due to the failure of following the maintenance and operation measures listed in the manual provided for that equipment.

A natural byproduct of air that is compressed is water. It is bound to appear inside the tank. Hence, it must be drained regularly in order to prevent the bottom of the tank from corroding. Moreover, the majority of the manufacturers of all air compressor companies insist that the tanks should be drained on a regular basis after each use. They also suggest closing the drain valves if one plans to store the compressor for a long period of time since this will stop moisture from entering the tank and causing it to corrode.

Testing the Tank for Corrosion

In order to test the compressor tank, the only sure method is to have it hydraulically pressure tested. However, sometimes this process itself will cost as much as a brand new tank. Another method to try could be using a rubber mallet on a tank empty of air. Hammer it on the sides, top, bottom, and ends and check if the tank causes an indent easily. If it did, then that could be a sign of a weak rusting spot.

Moreover, if the water that comes out is in the shade of rust red, that is another indication that corrosion has started inside the tank. Plus, placing a heavy-duty cage made of wires around the compressor would stop debris from flying if the compressor tank ever blows up. However, if they do, it is often along a connected seam.

Maintenance of the Air Compression

Since replacing a tank is an expensive option, it is always best to keep up with the maintenance of the air compressor in order to avoid the hassle of replacing it. Despite draining the tank regularly, there is another maintenance that must take place. Maintaining the air compressor is not as daunting as it might look and it is a crucial step in order to extend the lifespan of the machine. It is recommended to perform this routine at least once a year or per the guidelines of the manufacturer.

Step 1: Make sure that the oil inside the compressor is changed. Changing your air compressor oil might appear to be difficult, but it is quite a simple task. It is important in order to maintain the efficiency of the machinery.

Step 2: Do change and replace the air filter. Removing and installing the filter is really easy. Some air filters simply pull out by hand, while others are screwed on.

Step 3: It is also important to replace the worn-out compressor belt. Fitting in a new belt should be as easy as replacing the air filter. The compressors these days have a plastic cage surrounding the machine’s pulleys. However, previous models of the machines have their pulleys exposed; hence changing the belt will be an easy process.

In conclusion, it all comes down to how much attention you pay to your air tank compressors. In order to make sure that your tank stays in the best condition possible, it is important to follow the steps in order to keep up its maintenance. Or follow the maintenance schedule that was given by the manufacturer of your system. Do not expect your air compressor tanks to run smoothly without regular upkeeps. Taking some time out to perform these easy tasks will not only extend the lifespan of your machine, but it will also ensure that you don’t have to worry about your machine exploding on you anytime soon.

Related Video:

Water is incompressible