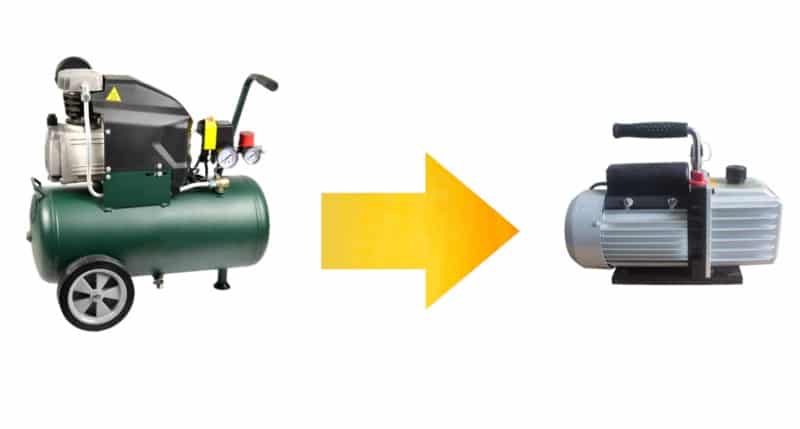

How To Make a Vacuum Pump with an Air Compressor

A vacuum pump and an air compressor function similarly as they both carry the same mechanism. Both of them suck the air outside to function. A vacuum pump is just like an air pump. An air compressor has a more specific function. It sucks the air from outside, compresses it and then pressures it into whatever object needs it like an engine or a tire. As the compressor is quite similar to a vacuum pump, you don’t need to invest in a separate vacuum pump. You can simply turn your air compressor into one.

Safety Tips

Safety comes first which is why you have to make sure you take the right precautions and follow the necessary instructions to avoid unwanted accidents

- Make sure there is no electrical connectivity while working

- Wear gloves

- Wear eye protectors

- Make sure clamps are perfectly tightened

- Make sure the hose is the right kind and the right size

- Make sure you reassemble all parts of the air compressor once you’re done

You can use a vacuum pump for your cars, bikes, light technology, medical purposes and etc. To make anything out of scratch, you will need the right tools and equipment. All these tools can be found under a budget and you already have an air compressor to work with.

You will need:

- Braided PVC hose pipe

- Nippers

- Scissors

- Hose barb

- Hose clamp

- Screwdriver

- Steel-filled epoxy

You have to understand how the air compressor works and how to open it. This is important for converting an air compressor to a vacuum pump.

- Pinch the end of the cap to remove it so you are able to see the motor pump of the air compressor. Push or pull the motor to see the cylinder. The cylinder is where the air intake happens before it is compressed.

- Now that you can view the cylinder, you can apply the steel-filled epoxy in the holes of the cylinder and attach the hose barb. Make sure you leave it for 1 day for it to be strongly attached. Make sure you’re able to attach the vacuum hose successfully after a day.

- Use a clamp for safety purposes while attaching the braided PVC hose pipe to the vacuum hose. Make sure you have a ¼ Inches PVC hose. The clamp will keep the pipe in place and avoid any unwanted incidents. Ensure the fitting is done properly

- Draw out a hole in the case. This hole is supposed to have the same diameter as the vacuum hose. Here you are creating an easy and smooth passage for the air to pass through. Use nippers to cut a hole and to insert the vacuum hose through the hole.

- This is the final step where you put the case back together. Close the case and put the cap back on. You finally have your own vacuum pump.

Related Video: